2 min read

Addressing the Impact of Fluctuating Gold on Your Jewelry Assortment

![]() Tamara de Rezende

:

May 23, 2024 6:01:44 PM

Tamara de Rezende

:

May 23, 2024 6:01:44 PM

In the jewelry industry today, merchandise planners, retail buyers, data analysts, and suppliers need to understand the impact that volatile commodity markets will have on their intake costs for a broad array of products. Typically, their actual cost (the inventory cost for any products ordered) is dependent on the price of gold at the time that the inventory was ordered or shipped.

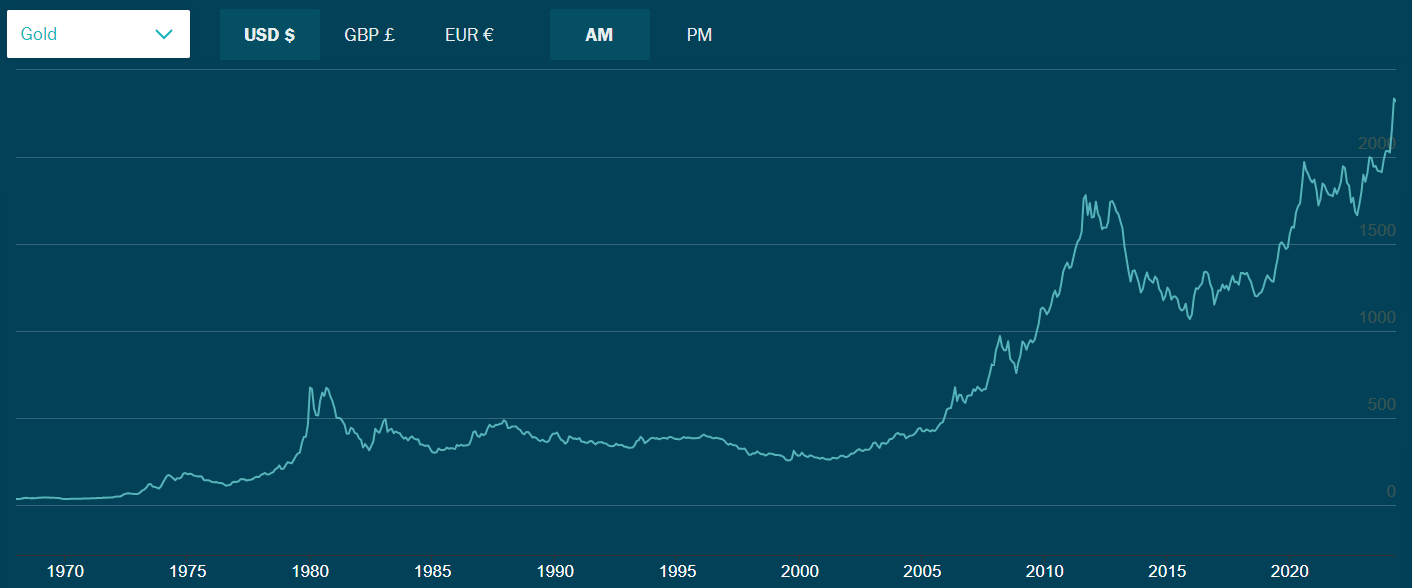

Growing risk exacerbated by a volatile gold market

Traditionally, legacy systems have not been designed to automate any of the overhead associated with enabling this calculus. The industry has been held back by a lack of technology designed specifically for this use case, and as a result data-driven jewelry companies undertake these operations manually in order to truly assess expected profitability, plan retail prices, manage cash flows, etc. This requirement has resulted in merchandising teams spending endless hours repricing the products that make up their assortments. Typically, this is limited to a once or twice a year task. However, given the recent volatility and dramatic increase in gold prices, many retailers may have executed an assortment recosting only to find their updated costs were already out-of-date. This means they would have to re-run the entire analysis again or risk making decisions using incorrect information.

Over the years, many companies in our industry have had to write off significant losses due to a lack of accurate real-time product costing that ultimately drives their intake costs; either over-buying due to lack of understanding of real cost of goods or over-pricing products at retail in a highly competitive, cost-sensitive environment.

Repricing jewelry products based on gold fluctuation

Consider the following example:

- A retailer has 5,000 products in their assortment

- With a finely-tuned manual process, it takes the retailer between 2-3 minutes to re-cost a single product, with 95% accuracy

- To re-cost the assortment, it will take between 10,000 - 15,000 minutes of staff time

- This translates to 160 - 250 hours of manual labor with ~250 incorrect prices

- With a dedicated tool, retailers can perform this task programmatically, avoiding unnecessary overhead and risk

Enter Loupe. Using our unified PIM/PLM, jewelers can automate gold incrementing across thousands of products in their assortment in a matter of seconds. In addition to the risk of product costs being out-of-date, relying on manual re-costing introduces the risk that prices have been recalculated incorrectly. With Loupe, you can guarantee with 100% accuracy that your costs have been recalculated with surgical precision.

The impact of automating this time-consuming process is a happier and much more productive workforce. Why ask humans to execute monotonous tasks that a computer can complete in an instant, rather than redeploying them to focus on value-add functions that depend on the human touch?